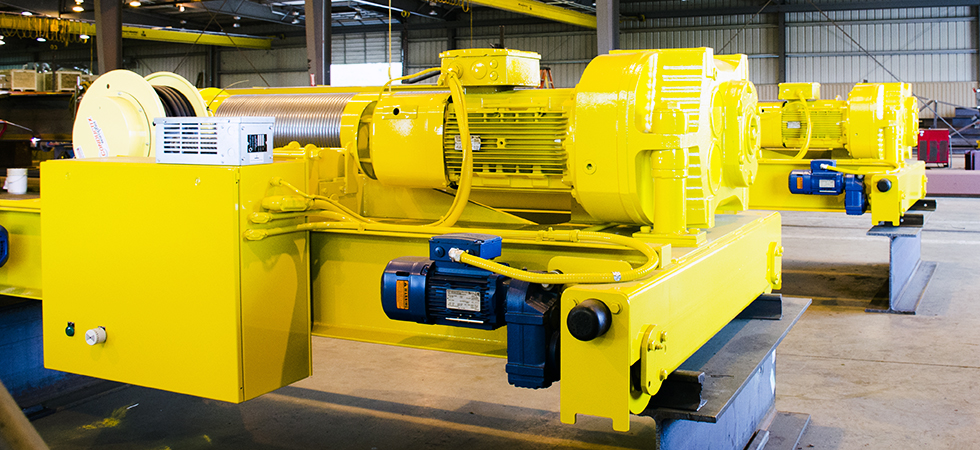

Built-Up Hoists

A Built-up Hoist is tailored for use in heavy-duty applications for users desiring long life and better durability. They also provide for easier maintenance. At ProservCrane Group we have spent significant time and resources researching and developing superior, highly-specialized Hoists which offer incomparable quality and low cost of ownership. Custom-built to your specifications, our Hoists are one of the most durable and reliable on the market today.

What makes our Hoists so superior is our approach to research and development. Our philosophy is to be the best in areas where we feature significant knowledge and expertise above the rest, and in return we expect the same proven results from our component partners. The outcome is the creation of an elite Hoist that surpasses industry standards and meets your criteria and demands; this includes receiving the latest in technology using non-proprietary parts that are widely available from any industrial component reseller.

Contact ProservCrane Group today.

We can help you design the best hoist

for your business.

We can help you design the best hoist

for your business.

Built-up Hoist up to CMMA Class “F” Service Indoor/Outdoor General

Class “A” thru Class “B”

- Double reeved for true vertical lift

- Drum and sheave rope ratio 24:1

- Rail sweeps on trolley provided as a standard

Hoist Motor

- Totally enclosed Non-Ventilated (TENV) AC 60 min. vector motor

- Class “H” Insulation

- Hoist motor is connected to gearbox via coupling for ease of maintenance

- Class “F” Thermostats (Klixon) in all three phases

- Multiple dips and brakes

- Cast iron frame and brackets

- Double shielded ball bearing, regreasable without disassembly

- Rugged bearingless encoder

Hoist Brake

- Standard vector disc brake rated at 150%

- Optional mill-duty shoe brake available

Trolley

- 400 BHN hardened wheels

- Double spherical, roller type bearings

- Trolley frame is an all-welded fabricated steel

- Polyurethane bumpers

- Line bored for precise traverse motion

- Central lube available upon request

- All components are serviceable from top deck

- Continuous Duty Class “F” insulation trolley motors

Trolley Motor

- SEW eurodrive helical reducers

- Totally enclosed non-ventilated (TENV)

- Continuous duty Class “F” insulation

- Disc brake rated at 125%

Paint

- A standard ProservCrane finish is a safety yellow industrial enamel

- For information on custom paint specifications contact our Sales Department.

Options

- Nested/central lube

- Motorized rotating bottom block

- Ribbed plate decking

- Other special features can be added to meet your application or individual requirements. Contact your Sales Representative for pricing information.

FOLLOW US